In the construction and renovation industries, the proper measurement of doors is crucial for ensuring functionality and aesthetic appeal. Door gauges serve as essential tools in this process, providing accurate measurements of door thickness, alignment, and placement. As we examine the inventory of door gauges, it becomes clear that these tools come in various types and styles, each designed to meet specific needs and applications.

At the heart of door gauge usage is the need to measure the thickness of doors. Standard doors typically range from one and three-eighths inches to two inches in thickness. However, variations exist, especially for specialized doors used in commercial settings or those designed for enhanced security. A precise gauge ensures that the door fits correctly within its frame, aligning properly with hinges and locks.

One of the most commonly used types of door gauges is the caliper gauge. This tool can be analog or digital, allowing users to choose based on their preferences and the level of precision required. Digital calipers are particularly popular for their ease of use and clear readouts, which facilitate quick measurements in a variety of settings. These gauges are versatile, allowing for measurements across different materials, including wood, metal, and composite materials.

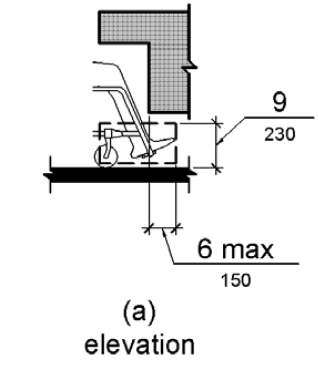

Template gauges also play a vital role in door installation. These tools assist in marking learn about ada knee clearance here out hinge and lock placements, ensuring that components are aligned accurately. By using a template gauge, installers can avoid repetitive measuring, streamlining the installation process while enhancing precision. This not only saves time but also reduces the risk of errors that can lead to functionality issues or safety concerns.

In addition to general-purpose gauges, there are specialized tools designed for specific types of doors. For example, hollow core doors require particular attention due to their unique construction. Specialized gauges for these doors help ensure that measurements are accurate and that the installation process accounts for the door’s characteristics. Understanding the distinct requirements of different door types is essential for achieving optimal results.

Maintaining a well-stocked inventory of door gauges is important for contractors and builders. Having a range of gauges available allows professionals to tackle various projects effectively and ensures they can take accurate measurements as needed. Regular calibration and maintenance of these tools are essential to preserve their accuracy, as wear and tear can affect performance over time.

With advancements in technology, new measuring options are entering the market. Laser measuring devices, for instance, provide a modern alternative to traditional gauges. These devices offer quick, precise measurements without direct contact, making them especially useful for large or complex projects. The incorporation of such technology into the toolkit can enhance efficiency and accuracy, benefiting the overall workflow.

In conclusion, the inventory of door gauges is a fundamental aspect of the construction and renovation process. From calipers to template gauges and specialized tools for different door types, having the right equipment is vital for ensuring accurate measurements and successful installations. As the industry evolves and technology advances, staying informed about the best tools and practices is crucial for professionals. Ultimately, a comprehensive inventory of door gauges not only improves the quality of work but also contributes to the